What We Do

Getting The Job Done Right: Capabilities

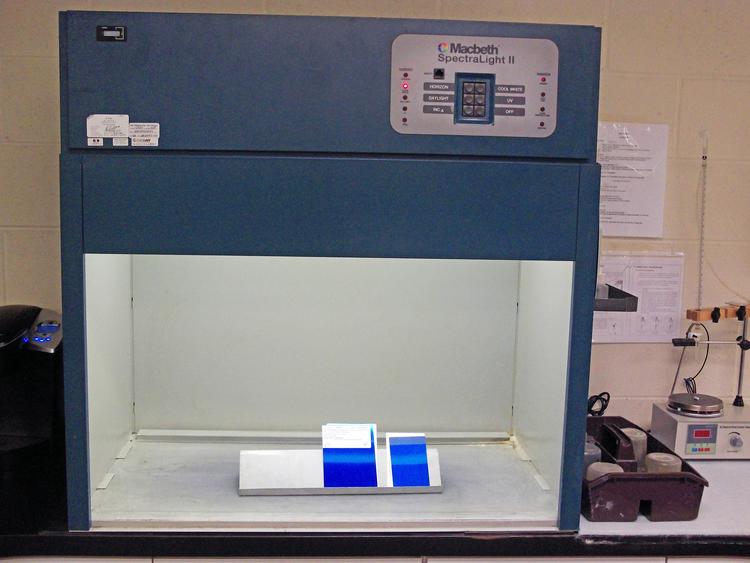

Your requirements are our first priority. We can handle virtually any project, and work with a variety of substrates. We’re highly experienced in coil coating building products, personal care items, sign & tag stock, lighting fixtures and other applications. We also offer custom color matching. Learn more about EDCOAT.

We work with all major paint companies and paint systems including: Polyester, Siliconized Modified Polyester (SMP), Kynar (PVDF), PVC and Epoxy, among others.

We provide complete slitting and warehousing services and work with a variety of metals, widths and thicknesses. Below is a list of our capabilities. Please contact us if you have questions or specifics you don’t see listed here.